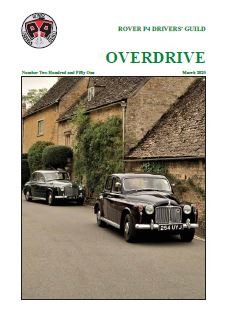

Picture by Andreas Riedmann

I started with planning the project after “accidentally” buying a suitable Rover 2S 150 turbine engine in 2012. By summer 2013 I started gathering all necessary parts, such as a Cyclops chassis, Suspension, Axles, and body parts. All those parts came from long gone donor vehicles, no saveable car was harmed in the process of creating Jet 1 R. After sand blasting followed the main body work, which was completed by the end of 2014 over winter time the body was transferred to the paint shop for the primer coats. During winter time the axle parts were modified (for example moving the diff upside down and to the far left) and the turbine engine adapted for car use. In Spring 2015 the body was finally ready for the top coats, assembly of the car started in June 2015 with the goal to have the car ready for “roll-out” for Ventilspiel in October 2015, a classic race car meeting at Austria’s F1 Track (Spielberg). It was quite a challenge to not only finish in time but to keep the standard of workmanship up during the final weeks. 3 weeks before the event this video was taken, on a day when helicopters trained at the nearby military airbase (so nobody even noticed the noise coming from our garden). The very first start was a static run of the engine to check for leaks and oil pressure, the second run was captured on tape and led directly to a first test drive on public roads (on trade plates), just I imagine Rover did back in the day. As a follow-up vehicle a square-dial Cyclops was used to keep things authentic!

To see footage of Georg's first test run, please click HERE

Ventilspiel 2015 was the goal for the whole project, but it was not without problems. The car developed a few leaks, which were easily rectified but not without a large burn on my forearm. Turbine exhausts get quite hot indeed! The whole exercise of driving it on the circuit was to prove functionality and shake the car down. Fast lap times were not achieved, mainly because of a drop in power after 3 to 5 laps. This led to a change in the fuelling system during the winter of 2015/16, which looked promising on the public road, but didn’t quite work out on the track. Overall the response from the first outing was very positive and enthusiastic!

To see footage of Georg's roll out and first time on the track, please click HERE

After the initial presentation of Jet 1 R in 2015 I was asked to present the car (along with a second turbine) at Austria’s largest historic vehicle exhibition in Tulln (comparable in style to the NEC) at the Stand of Austrias Rover club (www.roverclub.at/ausstellungen/tulln/2016) , which I did. When the car was on site I was teased several times if it really is a working car, so I kind of had to prove the point by running it. The clicking-sound during start up is the high-energy ignition unit, which fires a very intense spark every second. It works via charging a capacitor and then discharging it, the encountered electrical current is potentially lethal but necessary to ignite the compressed kerosene-air mixture.

To see footage at "Oldtimermesse Tullin" in 2016, please click HERE

After modifying the fuel system the car was driven again in October of 2016. Unfortunately the changes didn’t fully work out, it was now possible to drive 5 to 7 laps, but again with a power loss after a few laps. It was noted, that the oil temperature rose to an unacceptable level, even by aircraft standards. The Rover 2S150 uses Aeroshell Turbine oil and Jet 1 R utilizes a Land Rover oil cooler just as the original car does. After trying a few things it was decided that something serious must be going on inside the turbine, after the race meeting the power train was removed ready for repair. During this time I was in my final stages of my engineering study, followed by my first job as an project manager in industrial plant projects. As things go, repairing the turbine was postponed a few times.

To see footage of the second time at Ventilspiel 2016, please click HERE

During the time between 2016 and 2019 the turbine was thoroughly examined which resulted in the exchange of the gas-generator part of it (compressor and first turbine stage). The suspension was slightly altered and the front brakes changed to a different type of callipers and pads too. This time the car performed very well on track! It had full power over the course of a race stint (25 minutes) and the lap times decreased as well. The current fastest time for me is 2:25, which is on par with a slightly modified XK 140 as seen and passed in the second video. The car is very challenging to drive, because of the lack of throttle response (as suffered by all turbine cars…). It takes approx.. 2 seconds from the throttle input to a rise in power. For cornering you basically lift the throttle by 50% before the braking point and then get on it again immediately while also starting to brake with your left foot. At the apex of the turn full throttle is thus already applied and the brakes can be released, resulting in a tendency of drift/oversteer. The (governed) top speed of 120mph was achieved several times, the car is very stable at those speeds and the brakes (discs all round as Jet 1) work well too!

To see footage at "Ventilspiel" Heat 1 2019, please click HERE and for Heat 2, please click HERE